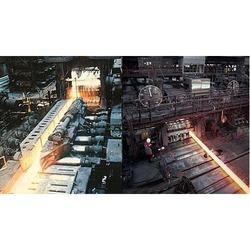

Hot Steel Rolling Mill

Hot Steel Rolling Mill Specification

- Type

- Hot Steel Rolling Mill

- Material

- Mild Steel

- Capacity

- 50-200 Ton/Day

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Voltage

- 380 V

- Power

- 150 kW

- Weight

- 6500 kg

- Surface Finish

- Smooth

- Mill Type

- Reversible

- Roll Diameter

- 350 mm

- Installation

- Onsite By Supplier

- Lubrication System

- Centralized Automatic

- Usage

- Rolling Steel Bars/Plates

- Cooling System

- Water Cooled

- Number of Stands

- 6

- Rolling Speed

- Up to 20 m/min

- Main Motor Type

- Three Phase Induction Motor

- Thickness Range

- 4 mm to 30 mm

- Drive Type

- Hydraulic

- Working Temperature

- 1100°C

- Width Range

- 600 mm to 1500 mm

- Foundation Required

- Yes

About Hot Steel Rolling Mill

we are manufacturer of Hot Steel Rolling Mill to our prestigious customers. These mills are widely used for steel forming process above its re-crystallization temperature. The offered mills are known for their optimum performance, fully automated operation, low maintenance and longer function life.

Other Information

- Pay Mode Terms: L/C (Letter of Credit), D/A (Documents Against Acceptance), T/T (Bank Transfer), Other

- F. O. B. Price Order: 10000000 USD

- Minimum Order Quantity:1 Set

- Port of Dispatch: FOB Mumbai

- Production Capacity: 20 Sets

- Delivery Time: 3-5 Months

- Packaging Details: 20' LCL/HCL

40" LCL/ HCL

Advanced Technology and Design

Our hot steel rolling mill leverages cutting-edge PLC automation, hydraulic drives, and a centralized lubrication system to enhance productivity and minimize downtime. Its reversible mill type and computerized controls allow for precise adjustments, ensuring consistent thickness and exceptional product quality every cycle.

Engineered for Versatility and Durability

Constructed from high-grade mild steel, this rolling mill supports a wide thickness and width range, adapting to a variety of bar and plate specifications. With a robust cooling system and automatic lubrication, it withstands demanding industrial environments and delivers sustained performance day after day.

Reliable Service and Expert Installation

As a leading exporter, manufacturer, and service provider in India, we ensure seamless onsite installation by skilled technicians. Ongoing support and tailored services further guarantee that your rolling mill operates safely and efficiently, maximizing output and extending equipment lifespan.

FAQs of Hot Steel Rolling Mill:

Q: How is steel processed in the hot steel rolling mill?

A: Steel billets are heated to around 1100C and passed through six reversible stands in the rolling mill. The material is reduced to desired thickness (4 mm30 mm) and width (600 mm1500 mm), then cooled by a water system, creating smooth-finished bars or plates.Q: What types of products can be manufactured using this hot rolling mill?

A: This mill is specifically designed for producing a broad range of steel bars and plates within the specified dimensions, ideal for construction, industrial manufacturing, and infrastructure projects.Q: When is onsite installation and commissioning provided?

A: Onsite installation is scheduled after purchase and shipment. Our expert team will arrive to install the foundation, set up the machinery, and oversee complete commissioning to ensure operational readiness.Q: Where can this rolling mill be installed?

A: The machinery requires a dedicated site with adequate foundation supportit is suitable for installation in steel manufacturing plants and industrial facilities across India and abroad, with guidance from our engineering team.Q: What are the key benefits of using a reversible six-stand rolling mill?

A: A reversible mill delivers precise control over thickness and surface finish while maximizing material use. The six-stand setup increases production flexibility and efficiency, ensuring higher yield and quality with every batch.Q: How does the centralized automatic lubrication system work?

A: The centralized system automatically distributes lubricants to all critical components, minimizing wear and maintenance. This ensures smooth operation and prolongs the life of the machine, reducing manual intervention.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rolling Mill Category

Hot Rolling Mill Plant

Computerized : Yes

Automatic Grade : Automatic

Type : Hot Rolling Mill

Control System : PLC Control

Structure Rolling Mill

Computerized : Yes

Automatic Grade : Automatic

Type : Structure Rolling Mill, Other

Capacity : High Production Capacity

Weight : 50 Tons

Control System : Other, Automated PLC Control

Rod Rolling Mill

Computerized : Yes

Automatic Grade : Automatic

Type : Rod Rolling Mill, Other

Capacity : 5001000 kg/hr

Weight : 10 Tons

Control System : Other, PLC Based

Rolling Plant Machinery for Steel Rolling Mills

Computerized : Yes

Automatic Grade : Automatic

Type : Other, Rolling Plant Machinery

Capacity : High Capacity

Weight : Heavyduty

Control System : Other, Advanced PLC Control

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free