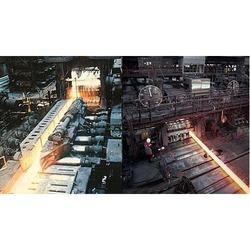

Hot Rolling Mill Plant

Hot Rolling Mill Plant Specification

- Type

- Hot Rolling Mill

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

Hot Rolling Mill Plant Trade Information

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Letter of Credit at Sight (Sight L/C), Cheque

- Delivery Time

- 3-8 Months

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- WOODEN BOX PACKINGS

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Central America, Middle East, South America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2015

About Hot Rolling Mill Plant

We hold expertise in offering supreme quality Hot Rolling Mill Plant to our valuable customers. Available with us at highly reasonable market prices, these machines are known for their fully automated operation, long functional life and minimum maintenance. As per the specifications provided by the customers, these machines can be custom designed.

Features:

- Options available as fully automatic, semi automatic & manual models Excellent production capacity

- Capable of performing heavy duty operations High speed

- Available for both small scale and large scale industries Accurate construction

- Excellent speed

- Guiding, cutting, cooling, coiling & handling equipment

We have been in this hot rolling mill plant and equipment industry for more than three decades now. This has helped us in become a technology advanced company in manufacturing precision hot rolling mills for long as well as flat products. Apart from this, we are also producing Individual components and rolling mill stands for hot rolling mill plants.

Various technical feasibility tests are conducted by us to improve our exiting hot rolling mill plants along with installation of individual components for TMT Bar Mill, Re-Bar Rolling Mill, Section Rolling Mill, Wire Rod Block Rolling Mill and Alloy Steel Rolling Mill.

Further, we are supported by in-house facilities to develop a reliable range of Hot Rolling Mill and Hot Rolling Mill Equipments for Flat & Long Products.

Scope of our Hot Rolling Mill Services includes:

- We offer Customized Light, Medium as well as Heavy Section Rolling Mill up-to 500,000 tons/year

- Wire rod Rolling Mill and TMT Bar Mill up-to 500,000 tons/year

- Diverse range of Gears up to 4000mm – 30 modules for any type of Hot Rolling Mill Stand

- Rolling Mill Stands for Hot Rolling Mill Plants up to 1000 mm

- Speed Reduction Gear Boxes up to 6000 kW rating for New and Existing Hot Rolling Mill Stand or Plant

- EOT Cranes up to capacity of 100 tons

- AOD Converter Shop & LD Converter Shop

- Hardened and Ground Gears and Gear Boxes up to 2000mm - 25 modules

Key Product Areas

- We are engaged in the production of Hot Rolling Mill Products for last 30 Years. Our Hot Rolling Mill Solutions includes:

- Wire Rod Rolling Mill up to 500,000 tons per year along with European technology

- Heavy Section Rolling Mill and Light Section Rolling Mill / Structure Rolling Mill up to 500,000 tons per year

- Re-Bar Rolling Mill upto 500,000 tons per year with slit rolling European technology.

- Steel Rolling Mill Stands such as Pre Stress Rolling Mill Stands, Housing Less Rolling Mill Stands, Universal Rolling Mill Stands for Horizontal and Vertical Rolling Mill Stands (V/H Type), Section Rolling Mill / Structure Rolling Mill

- Broad array of Gear and Gear Boxes including Reduction Gear Boxes, Pinion Gear Boxes, Reduction cum Pinion Gear Boxes with 4000mm OD and 30 modules and up to 6000 kW rating

- Profile and Hardened ground gears and gears boxes such as Reduction gear boxes, pinion gear boxes, Reduction cum pinion gear boxes with 2000mm OD and 25 modules and up to 6000 kW rating

- AOD converter Shop & LD Converter Shop

- EOT Cranes with capacity up to 100 tons

- Gear Couplings for all applications

- Shearing machines such as continuous type flying shear, start and stop type flying shears, crank type flying shears, cold shears, crop and coble shears, billet cutting shear for both M.S and S.S.

- Full range of guiding equipments including twist pipes, entry guide boxes and slitting boxes (Slit Guide Box)

- Allied equipments for steel rolling mill such as turn-over cooling beds, automatic cooling beds (Rack Type cooling beds), TMT quenching boxes, Section and bar straightening machines, twin channels and hot/cold rolling mill for both ferrous and non ferrous metals.

- Fabrication, Machining and assembly up to 100 tons in single piece as per the clients designing and specifications

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rolling Mill Category

Structure Rolling Mill

Computerized : Yes

Capacity : High Production Capacity

Automatic Grade : Automatic

Type : Structure Rolling Mill, Other

Weight : 50 Tons

Material : Steel

Block Rolling Mill

Computerized : Yes

Capacity : 90180 Tons per Hour

Automatic Grade : Automatic

Type : Other, Block Mill

Weight : 1525 Tons

Material : Mild Steel

Cold Rolling Mill Plant

Computerized : Yes

Capacity : 2060 Ton/day

Automatic Grade : Automatic

Type : Other, Cold Rolling Mill Plant

Weight : 18000 kg

Material : Mild Steel

Bar Rolling Mill

Computerized : Yes

Capacity : 10150 Tons/Day

Automatic Grade : Automatic

Type : Other, Bar Rolling Mill

Weight : Customizable

Material : Mild Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free