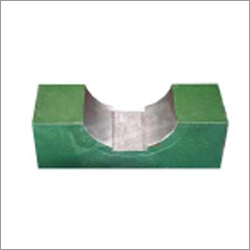

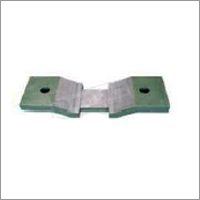

Fibre Bearing Choke

Fibre Bearing Choke Specification

- Type

- Fibre Bearing Choke

- Material

- Fiber Reinforced Composite

- Application

- Textile Machinery and Spinning Industry

- Shape

- Round

- Size

- Standard and Custom Sizes Available

- Tolerance

- ±0.02 mm

- Corrosion Resistance

- Yes

- Temperature Resistance

- Up to 120°C

- Lifespan

- Long Service Life in Textile Environments

- Color

- Light Brown

- Maintenance

- Low Maintenance

- Mounting

- Direct Fit

- Product Code

- FBC-157

- Load Capacity

- High, Suitable for High-Speed Operations

- Finish

- Smooth Surface Finish

About Fibre Bearing Choke

Our organization is specializes in manufacturing, exporting and supplying optimum grade Fibre Bearing Choke. The product provided by us is manufactured under the vigilance of our adroit professionals in tune with set international standards by utilizing premium quality raw material with the help of latest technology. Our offered product is generally used to grip the fibre bearing owing to its rugged construction, perfect finish and corrosion resistance nature. In addition to this, clients can get this Fibre Bearing Choke from us in bulk quantity at pocket friendly prices.

Features:

-

Anti corrosive

-

Easy installation

-

Impeccable finish

-

Sturdy construction

Technical Features:

|

Material |

Class IV Forged Steel |

|

Sizes |

As Per Bearing Size |

Precision Engineering for Demanding Environments

The FBC-157 Fibre Bearing Choke is meticulously engineered to meet the rigorous needs of high-speed textile machinery. Its precise tolerance of 0.02 mm and smooth finish help reduce friction and minimize wear, extending operational reliability. The robust fiber reinforced composite construction delivers high strength while maintaining lightweight properties, supporting seamless integration into various textile applications.

Enduring Performance and Low Maintenance

With exceptional corrosion resistance and temperature endurance up to 120C, the FBC-157 endures the harshest spinning environments. Its long service life and low maintenance feature reduce downtime and operational costs, making it ideal for busy textile manufacturing units. Maintenance is straightforward, helping you optimize textile machinery performance without frequent interruptions.

FAQs of Fibre Bearing Choke:

Q: How is the Fibre Bearing Choke (FBC-157) installed in textile machinery?

A: The FBC-157 is designed with a direct fit mounting system, allowing for straightforward installation into standard or custom housing in textile machinery. Its precise dimensions ensure a secure and stable fit, minimizing installation time and effort.Q: What makes the FBC-157 suitable for high-speed textile operations?

A: This choke features a high load capacity, smooth surface finish, and stringent tolerance of 0.02 mm, all of which reduce friction and vibration. These characteristics ensure reliable performance under high-speed conditions, typical in textile manufacturing processes.Q: When should you consider using a fibre bearing choke in spinning machinery?

A: A fibre bearing choke should be used when you require high durability, low maintenance, and strong resistance to temperature and corrosionattributes essential for continuous, high-speed spinning operations in textile environments.Q: Where can the FBC-157 be applied within the textile industry?

A: The FBC-157 is primarily used in textile machinery involved in spinning and winding applications. Its robust design supports diverse machinery types across textile mills and spinning facilities.Q: What benefits does the fibre reinforced composite material offer?

A: The fibre reinforced composite construction provides excellent strength-to-weight ratio, corrosion resistance, and dimensional stability, while also reducing the overall wear on machine components. This leads to a longer service life and less frequent replacements.Q: How does the FBC-157 contribute to lower maintenance needs?

A: Its superior material properties and smooth surface reduce the accumulation of dust and debris, minimizing the need for regular cleaning and maintenance. This leads to fewer machine stoppages and improved operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rolling Mill Accessories Category

Counter Pulley

Material : Cast Iron / Mild Steel

Application : Industrial Machinery, Conveyor Systems

Type : Counter Pulley

Fibre Key Hanging Choke

Material : Fibre

Application : Electrical Lighting Circuits

Type : Key Hanging Choke

Brackets Rolling

Material : Stainless Steel

Application : Industrial Support and Fixing

Type : Rolling Bracket

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS