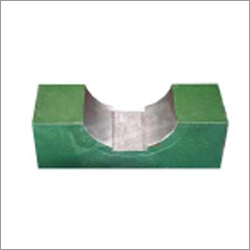

Counter Pulley

Counter Pulley Specification

- Type

- Counter Pulley

- Material

- Cast Iron / Mild Steel

- Application

- Industrial Machinery, Conveyor Systems

- Corrosion Resistance

- Yes

- Color

- Grey / Custom as per requirement

- Load Bearing Capacity

- Up to 2 tons

- Grooves

- Single / Multiple Grooves

- Usage

- Extensively used to change direction of belt drive

- Surface Finish

- Painted / Powder Coated

- Diameter Range

- 100 mm to 600 mm

About Counter Pulley

Our renowned company is considered amongst the prominent manufacturer, exporter and supplier of the best quality Counter Pulley that is highly demanded in rolling mills. Our offered pulley is designed to support movement and also to change of direction of a cable & belt along its circumference. This pulley is manufactured under the vigilance of our experienced professionals following industry defined guidelines by making use of premium grade raw material and progressive technology. Moreover, we provide this Counter Pulley in various sizes at rock bottom prices to the clients.

Features:

-

Sturdiness

-

Resistant against corrosion

-

High strength

-

Fine finish

Counter Pulley is generally used for Rolling mills

-

Material : Graded Cast Iron

-

Sizes : Up to 2150 mm Dia

-

Grooves : 4 to 26 (as per requirement) Section E or D

-

Shaft : Forged Steel

-

Brackets : Cast Irom

-

Bearings : Imported Bearings

Precision Manufacturing for Demanding Applications

Our Counter Pulleys are meticulously manufactured to meet the rigorous demands of industrial operations. With precision engineering and high-quality materials, they deliver dependable performance in conveyor systems and machinery. The customizable features allow integration into a variety of setups, ensuring operational flexibility across industries.

Corrosion Resistance and Load Capacity

Designed to withstand challenging environments, the Counter Pulley boasts a painted or powder-coated finish for superior corrosion resistance. The capacity to support up to 2 tons makes it ideal for heavy-duty usage, providing longevity and reliability even under substantial loads, ensuring smooth belt direction change and minimal maintenance requirements.

FAQs of Counter Pulley:

Q: How is the surface finish of the Counter Pulley beneficial for industrial environments?

A: The painted or powder-coated surface finish enhances corrosion resistance, increasing the pulleys durability and reducing maintenance needs in harsh industrial settings.Q: What diameter options are available for the Counter Pulley, and how do I select the right size?

A: Diameters range from 100 mm to 600 mm. The selection depends on your specific belt drive configuration and application requirements; our team can assist you in choosing the optimal size for load and operational demands.Q: When should I use a Counter Pulley with multiple grooves instead of a single groove?

A: Multiple grooves are ideal for applications requiring the redirection or operation of several belts simultaneously, while a single groove suits setups with one belt. This flexibility accommodates diverse machinery needs.Q: Where are Counter Pulleys typically installed within industrial setups?

A: Counter Pulleys are commonly integrated into conveyor systems and industrial machinery where changing or redirecting the direction of belt drives is essential for workflow and power transmission.Q: What materials are available for Counter Pulley construction, and what are their advantages?

A: You can choose between cast iron and mild steel. Cast iron offers high strength and wear resistance, whereas mild steel provides flexibility in custom fabrication and lighter weight for specific applications.Q: How does the Counter Pulley contribute to the efficiency of conveyor systems?

A: By effectively redirecting the belt drive, the Counter Pulley ensures smooth operational flow, reduces stress on drive components, and enhances overall system efficiency, leading to increased productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rolling Mill Accessories Category

Fibre Bearing Choke

Application : Textile Machinery and Spinning Industry

Material : Fiber Reinforced Composite

Type : Fibre Bearing Choke

Vertical Stand

Application : Industrial Equipment Support

Material : Stainless Steel

Type : Vertical Stand

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free