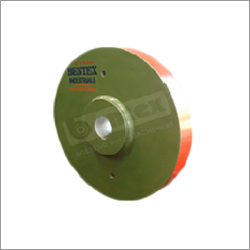

Plate Type Flywheel

Plate Type Flywheel Specification

- Type

- Plate Type Flywheel

- Material

- Cast Iron

- Capacity

- Up to 1 Ton

- Computerized

- No

- Control System

- Manual

- Power

- Mechanical Driven

About Plate Type Flywheel

Backed ourselves with sound amenities and talented personnel, we have emerged as the leading manufacturer, exporter and supplier of superior quality Plate Type Flywheel that is basically attached to the drive shaft. Our offered flywheel is manufactured taking into account maximum possible energy fluctuation encountered in services. Manufactured by utilizing quality assured raw material and pioneer technology, the flywheel offered by us is made available as per the specifications detailed by our renowned clients. Offered Plate Type Flywheel is made available at rock bottom prices to the clients.

Features:

-

Statically, dynamically and mechanically balanced

-

Fully machined and bored on VTL up to zero oddness

-

Genuine and branded heavy duty anti friction spherical roller bearings are installed

-

Flywheel are designed taking into account maximum possible energy fluctuation encountered in services to install

Technical Features

-

Material : Mild Steel/Graded Cast Iron

-

Weight : Maximum up to 20 M.T.

-

Revolution Range : up to 1000 RPM

-

Shafts : Forged EN-Series

-

Pedestal : Cast Iron with precision (machines Plummer Blocks)

-

Bearing : Antifriction Roller bearing, Single and Multi-row, depending on load & speed analysis

-

Base Plates : M.S. Base Plates duly machined and drilled for (Plumber Blocks.)

-

Balancing : Statically, dynamically and mechanically balanced.

-

Anchor/foundation Bolts : M. S. Steel

Robust Construction and Durable Performance

This plate type flywheel is crafted from high-grade cast iron, ensuring exceptional durability and robust construction. Its design supports industrial machines and mechanical presses that require consistent and reliable power transmission. The polished surface and corrosion-resistant properties contribute to prolonged operational life, making the flywheel an ideal choice for heavy-duty applications in various industrial settings.

Precision Engineering and Superior Surface Finish

With a diameter range from 300 mm to 2000 mm, the flywheel delivers precise performance thanks to tight tolerances of up to 0.05 mm. Its surface is expertly polished, not only enhancing aesthetic appeal but also minimizing friction during operation. As a result, the flywheel guarantees optimal mechanical efficiency in any installation, and the key slot feature simplifies seamless mounting.

FAQs of Plate Type Flywheel:

Q: How is the plate type flywheel installed in industrial machines?

A: The flywheel is designed with a key slot mounting feature, allowing for straightforward and secure attachment to the shaft of industrial machines or mechanical presses. Proper alignment and securing with the appropriate key ensure optimal performance and safety.Q: What benefits does the cast iron construction provide for this plate type flywheel?

A: Cast iron offers excellent robustness, wear resistance, and longevity. These attributes enable the flywheel to withstand high mechanical stresses and provide stable power transmission, crucial for industrial applications demanding reliable operation over extended periods.Q: When should the flywheel be used in mechanical presses?

A: The flywheel is best utilized in mechanical presses that require the conversion and storage of rotational energy to drive the press mechanism. It is suitable for operations demanding consistent torque and energy delivery throughout the machines cycle.Q: Where can this plate type flywheel be effectively applied?

A: It is ideal for use in industrial machines, manufacturing plants, mechanical presses, and other machinery that require stable and efficient mechanical power delivery. Companies involved in heavy-duty production lines will benefit from its capabilities.Q: What is the manufacturing process used for this flywheel?

A: The flywheel is manufactured using advanced casting techniques for shaping high-grade cast iron. Precision machining ensures adherence to the tight 0.05 mm tolerance, and a professional polishing process delivers a smooth, corrosion-resistant finish.Q: How does the surface finish contribute to the flywheels performance?

A: The polished surface reduces friction and wear, promoting smoother operation and lower maintenance requirements. This finish also enhances corrosion resistance, extending the flywheels service life in demanding industrial environments.Q: What key advantages does this flywheel offer to users?

A: Users benefit from its durability, corrosion resistance, and robust construction. The flywheel supports a mechanical-driven system with manual control, offers precise energy storage, and integrates easily via the key slot mounting, resulting in dependable performance for various industrial needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Flywheel Category

Metallic Flywheels

Control System : Other, Mechanical

Computerized : No

Material : Cast Iron / Mild Steel / Alloy Steel

Capacity : Up to 1000 kg

Type : Other, Flywheel

Automatic Grade : Other, Manual / SemiAutomatic

Rim Type Flywheel

Control System : Other, Mechanical

Computerized : No

Material : Cast Iron

Capacity : Custom as per requirement

Type : Other, Rim Type Flywheel

Automatic Grade : Manual

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free