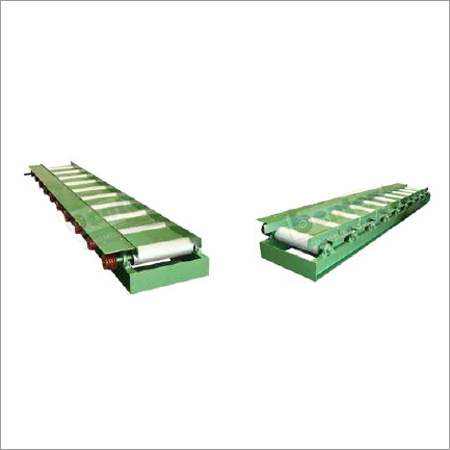

Conveyor Repeaters & Y Table

Conveyor Repeaters & Y Table Specification

- Belt Type

- PVC / Rubber, customizable

- Thickness

- 3 6 mm

- Power Source

- Electric

- Surface Finish

- Powder coated / galvanized

- Type

- Conveyor Repeater & Y Table

- Belt Conveyor

- Available as customization

- Roller Conveyor

- Standard specification

- Resistant Feature

- Corrosion and wear resistant

- Load Capacity

- Up to 1500 kg per unit

- Power

- 1.5 3 kW

- Speed

- Variable, up to 50 m/min

- Usage & Applications

- Transfer and routing of goods, material handling in assembly line, packaging and dispatching

About Conveyor Repeaters & Y Table

Conveyor Repeaters & Y Table

These are generally used for transfer for hot/cold steel material from one station to other station. These are used for Roughing, Intermediate, Finishing mills, Section Mill, Heavy round Squere, Flat, TMT, Girder, Bar Mills Etc.

Technical Specifications

- Material : Graded Cast Iron, Seamless Pipes, Forged Steel Round

- Rounds : H.C. Steel

- Base Plate/Pedestal : Fabricated from Mild Steel Prime Plate and Structure Steel

- Bearing : Antifriction Roller bearing,

- Bearing Block : Heavy Duty Cast Steel / Graded Cast Iron

Superior Material Handling Performance

Designed for heavy-duty industrial applications, these conveyor repeaters and Y tables streamline the transfer and routing of heavy goods. Their load capacity reaches 1500 kg per unit, making them ideal for demanding assembly lines, packaging units, and dispatch centers. With a robust construction and high-quality materials, they excel in performance and reliability.

Customizable and Durable Construction

Whether you require a roller conveyor as the standard or a belt conveyor tailored to your needs, this product can be configured with PVC or rubber belts. Featuring powder-coated or galvanized finishes and adjusting thickness from 3 to 6 mm, these conveyors withstand corrosion and wear, offering long-term durability.

Flexible Speed and Efficient Power Usage

Fitted with electric motors rated between 1.5 and 3 kW and supporting variable speed up to 50 m/min, these systems provide precise control over material flow. This flexibility enables adaptation to different operational tempos and maximizes productivity within any material handling process.

FAQs of Conveyor Repeaters & Y Table:

Q: How are Conveyor Repeaters & Y Tables typically used in industrial settings?

A: Conveyor Repeaters & Y Tables effectively transfer and route goods for material handling processes in assembly lines, packaging, dispatching, and other industrial operations. Their robust construction ensures efficient movement of heavy materials across different workflow stages.Q: What advantages does the corrosion and wear resistance provide?

A: Corrosion and wear resistance significantly extends the operational lifespan of the conveyors, reducing maintenance needs and ensuring consistent performance even in harsh or demanding environments such as factories or warehouses.Q: When should I consider customizing the belt type or surface finish?

A: Customization of the belt type (PVC or rubber) or surface finish (powder-coated or galvanized) is recommended when dealing with specific material handling conditions, such as exposure to chemicals, moisture, or varying temperature ranges, to optimize durability and function.Q: Where can these conveyor systems be installed?

A: These conveyor systems can be installed in diverse industrial locations such as assembly lines, packaging plants, and warehouses where efficient routing and movement of goods are essential for streamlined operations.Q: What is the process for integrating a Conveyor Repeater & Y Table into an existing line?

A: Integration usually involves assessing load and speed requirements, selecting the appropriate conveyor model and configuration, and implementing the system with support from the manufacturer, ensuring compatibility with current operations and minimal downtime.Q: What benefits do variable speed options provide in material handling?

A: Variable speed options allow operations to adjust conveyor movement based on changing workflow needs, enhancing process flexibility, preventing bottlenecks, and helping to optimize throughput in material handling and transport tasks.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Industrial Conveyor Category

Conveyors Machine

Roller Conveyor : Other, Optional

Surface Finish : Powder Coated

Power Source : Electric

Resistant Feature : Other, Corrosion Resistant

Thickness : 515 mm

Usage & Applications : Material Handling, Packaging, Assembly Line

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free