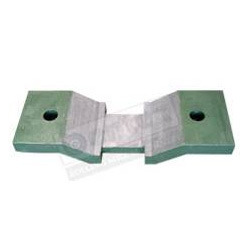

Bearing Choke

Bearing Choke Specification

- Capacity

- Customizable

- Shape

- Round with Flange

- Drive Type

- Belt & Direct Driven

- Features

- Corrosion Resistant, Durable, High Strength

- Surface Finish

- Smooth Machined

- Noise Level

- Low

- Usage & Applications

- Machinery, Electric Motors, Pumps, Industrial Equipment

- Motor Power

- Adaptable

- Lubricating System

- Grease/Oil Lubricated

- Size

- Standard/Custom

- Diameter

- 65 mm 150 mm

- Product Type

- Bearing Choke

- Material

- Cast Iron

- Technology

- Centrifugal Casting

- Power Source

- Electric

- Power

- 2 HP 15 HP

- Voltage

- 220-440 V

- Pressure

- 4 bar 8 bar

- Surface Treatment

- Galvanized

- Dimension (L*W*H)

- 150mm x 75mm x 75mm (Approx)

- Weight

- 3-8 kg

- Color

- Grey

- Packaging Type

- Wooden Box/Carton

- Customisation

- Available as per Drawing or Sample

- MOQ

- 10 Pieces

- Port Type

- Flange/Split

- Compatibility

- Available for Multiple Shaft Sizes

- Temperature Range

- -20°C to 120°C

- Maintenance

- Low Maintenance

- Hardness

- 60-70 HRC

- Mounting Type

- Horizontal/Vertical

About Bearing Choke

established in the year 1996, is one of the leading manufacturer, Bearing Choke, which are made from qualitative raw material to provide optimum performance to the end users. It is used in rolling mills for cold as well as hot rolling processes. these products are widely demanded in various industries. These products are widely demanded in various industries.

Details:

- Material: Class IV Forged Steel

- Sizes: as per bearing size

Premium Construction & Design

Crafted using centrifugal casting technology, this cast iron Bearing Choke provides superior strength and longevity. The surface is precisely machined and treated with galvanization, ensuring corrosion resistance and a smooth finish suitable for demanding industrial settings.

Versatile Mounting & Compatibility

Supporting both horizontal and vertical mounting, the Bearing Choke is adaptable to different shaft sizes and can be customized in size and configuration. Its round, flanged shape and both split and flange port types enhance compatibility for a wide range of machinery and applications.

Low Maintenance, High Performance

With a low-noise operation and efficient grease or oil lubrication system, this Bearing Choke requires minimal upkeep while consistently delivering high performance. The durable construction minimizes wear, extending lifespan even in harsh environments.

FAQs of Bearing Choke :

Q: How is the Bearing Choke typically installed?

A: The Bearing Choke can be mounted either horizontally or vertically depending on your equipments requirements. Installation should follow the provided guidelines, and custom mounting options are available to ensure compatibility with your specific machinery and shaft sizes.Q: What types of equipment can use this Bearing Choke?

A: This Bearing Choke is designed for machinery, electric motors, pumps, and various types of industrial equipment. Its compatibility with both belt and direct-driven systems enhances its versatility for many industrial applications.Q: When should I consider customising the Bearing Choke?

A: Customization is recommended when your application requires specific dimensions, unique mounting configurations, or matches with non-standard shaft sizes. Simply provide your drawings or samples, and we can manufacture bearing chokes tailored to your specifications.Q: Where is the product manufactured and supplied from?

A: The Bearing Choke is manufactured, exported, and supplied from India, serving both domestic and international clients as a reliable exporter, manufacturer, service provider, supplier, and trader.Q: What is the maintenance process and how often is it needed?

A: This Bearing Choke features a low-maintenance design. Routine checks on lubricationeither grease or oilshould be done according to your operational schedule. Its corrosion-resistant, durable build reduces the frequency of maintenance required.Q: What are the key benefits of using this Bearing Choke?

A: Key benefits include corrosion resistance, high strength, durability, low noise operation, and adaptability to various power and pressure requirements. The products customizable nature ensures optimal fit for your equipment, providing streamlined performance with minimal maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rolling Mill Chocks Category

Bearing Chock Accessories

Surface Finish : Polished

Color : Metallic

Product Type : Other, Bearing Chock Accessories

Material : Metal

Shape : Round

Surface Treatment : Other, Heattreated

Fiber Bearing Choke

Surface Finish : Smooth

Color : Green

Product Type : Other, Fiber Bearing Choke

Material : Fiber

Shape : Cylindrical

Surface Treatment : Painted

Fiber Key Hanging Choke

Surface Finish : Smooth

Color : Green

Product Type : Other, Key Hanging Choke

Material : Fiber

Shape : Rectangular

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free