Brackets Rolling

Brackets Rolling Specification

- Type

- Rolling Bracket

- Material

- Stainless Steel

- Application

- Industrial Support and Fixing

About Brackets Rolling

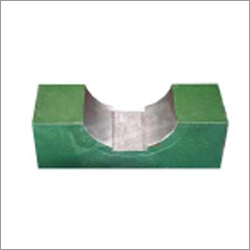

Cast Iron Brackets

We Supply various kind of rolling mill Brackets which are manufactured & designed as per Steel Rolling mill Requirements

- Material : Cast Iron, Graded Cast Iron Dully machined & grinded.

- Size : As per Requirement of Spherical Roller Bearing

Unmatched Strength and Durability

Built from premium stainless steel and polished for long-lasting corrosion resistance, our rolling brackets guarantee superior strength. With a load capacity of up to 150 kg and a 5 mm thickness, these brackets are a dependable choice for supporting heavy fixtures in industrial settings.

Engineered for Industrial Efficiency

The L-shaped, wall-mounted design provides stable support and optimized space utilization. Smooth rolling action ensures effortless repositioning, simplifying maintenance and adjustment tasks for large equipment and fixtures in factories or warehouses.

FAQs of Brackets Rolling:

Q: How are the Brackets Rolling installed for heavy-duty support?

A: These brackets are wall-mounted using suitable anchors and fasteners compatible with the brackets size and weight capacity. The installation process involves securing the L-shaped bracket to the wall, ensuring it is firmly fixed for supporting up to 150 kg.Q: What applications are best suited for these rolling brackets?

A: They are ideal for industrial support and fixing tasks, particularly for mounting heavy fixtures, equipment, or shelves that require stability and occasional repositioning. The smooth rolling feature makes them especially useful in environments where frequent adjustment is required.Q: When should stainless steel rolling brackets be chosen over other types?

A: Choose stainless steel rolling brackets when you need superior corrosion resistance, substantial load capacity, and a durable finish. These brackets are particularly beneficial in factories, workshops, and processing units exposed to moisture or chemicals.Q: Where are these brackets commonly used within industrial facilities?

A: Youll find these brackets supporting machinery, storage units, and large equipment on walls in manufacturing plants, warehouses, and service workstations throughout the industrial sector.Q: What process ensures their corrosion resistance and load capacity?

A: They are manufactured from high-grade stainless steel and polished to enhance corrosion resistance. Rigorous quality checks confirm a consistent thickness of 5 mm and load-bearing ability up to 150 kg.Q: How does the smooth rolling action benefit daily operations?

A: The smooth rolling mechanism allows users to easily reposition fixtures, reducing downtime and physical effort during maintenance or layout changes. This feature adds significant operational flexibility in dynamic work environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Rolling Mill Accessories Category

Fibre Bearing Choke

Application : Textile Machinery and Spinning Industry

Material : Fiber Reinforced Composite

Type : Fibre Bearing Choke

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS